Yemen company for ghee and soap industry

Quality Assurance

The Quality Assurance Department conducts all control and quality assurance processes for all types of raw materials involved in the manufacturing process, and through adjusting the intermediate and final production stages to ensure the safety of transport, trading and storage operations in the company and customer stores.

This is achieved by various specialized laboratories distributed to all the company's plants which are equipped with the latest testing techniques and according to national and international accredited references (CODEX, ODCO, AOCS, AOAC ..... etc) under the supervision and work of a specialized cadre, trained and highly qualified.

INTEGRATED MANAGEMENT SYSTEM (IMS) – POLICY

INTEGRATED MANAGEMENT SYSTEM– OBJECTIVES

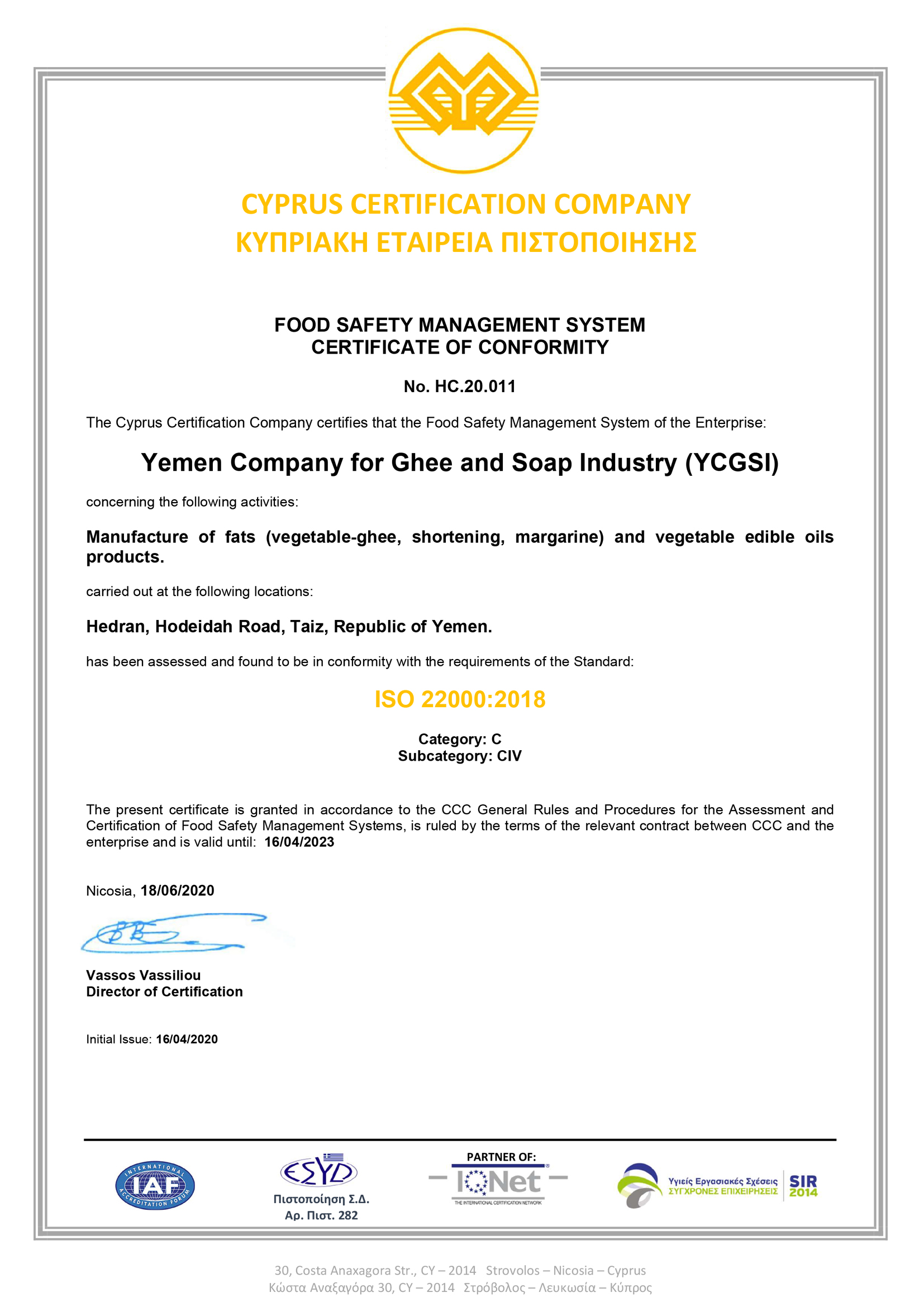

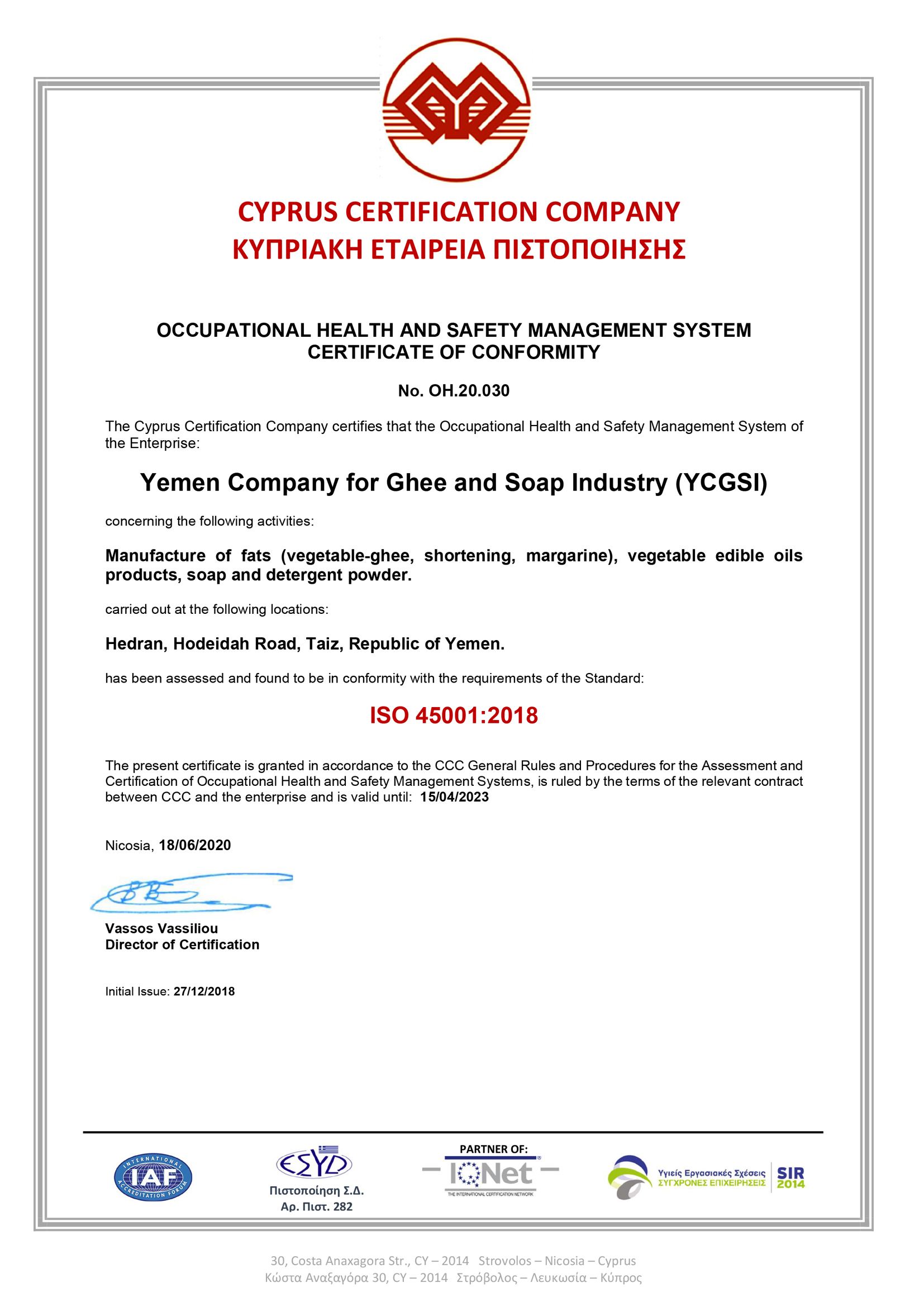

Global systems implemented by the company / certificates

Yemen company for ghee and soap industry

Our Environment

The company strives to prevent pollution, conserve natural resources and develop continuous environmental ...

Read more

Our Social Responsibility

What distinguishes HSA & Partners Group is their responsibility towards the society and YCGSI is ...

Read more

Research and Development

To meet the requirements of the customer continuously ,products are developed to new products to ...

Read more